For most of my working life, I have made my living as an engineer. I have held the titles of Design, Manufacturing, Plant, Tool and Process Engineer. I have designed many tools, production layouts and defined processes at a variety of manufacturing facilities in and around the Detroit, Michigan area.

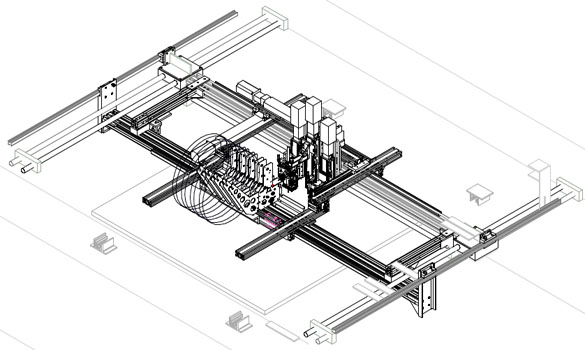

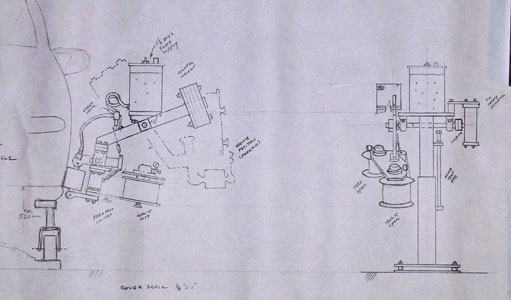

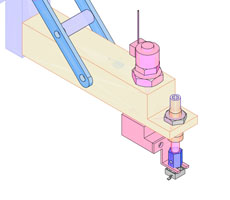

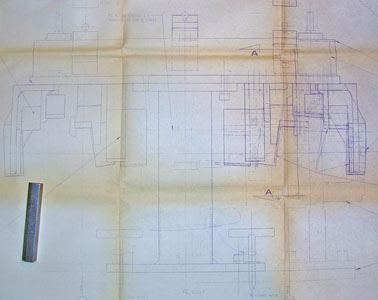

I still enjoy a good design challenge though and have CAD systems at my home studio (Solidworks Premium 2012 and Vectorworks v.2008). CAD is just a tool itself. It doesn't design a thing, it still takes a human for that. Started on a drafting board in the mid 70's and manual design is fun too, but CAD offers much greater control and crash detection. I started with UG v5 back in 1985.

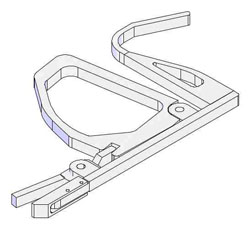

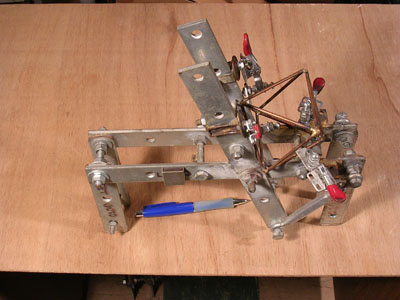

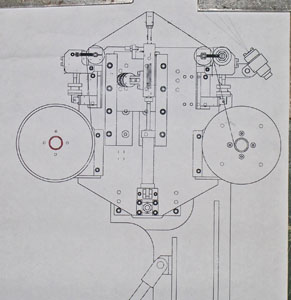

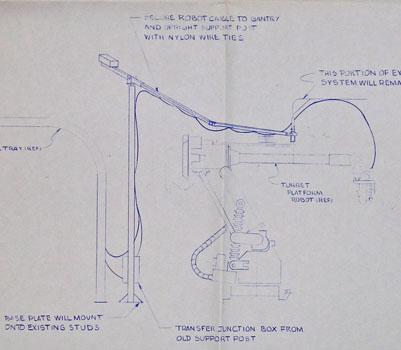

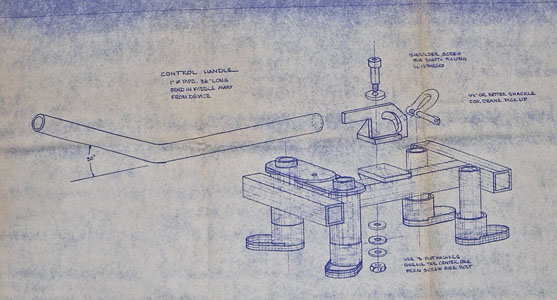

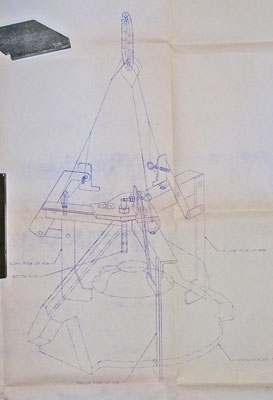

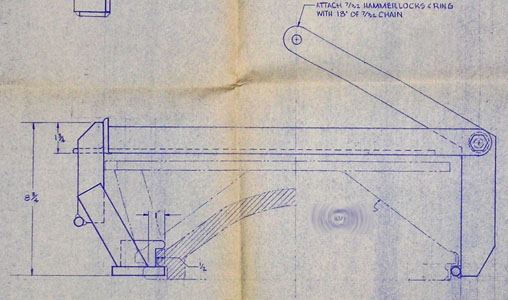

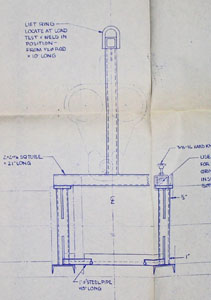

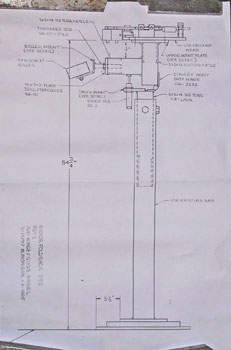

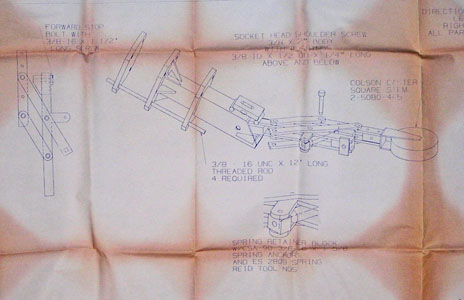

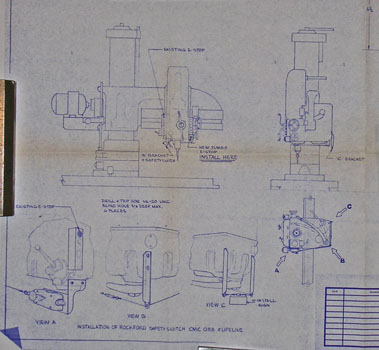

Design challenges that I have solved span a wide range of manual and automatic tools. Most have been assembly tools and fixtures as opposed to tools at the cutting head. The vast majority were never photographed and a few that were are shown below. The keys to designing a sucessful tool are using common sense and listening to people.

I believe that the best tool is no tool. Sometimes a process change can make the need for a device go away. When this is not possible, I try to keep it as simple as possible. If a hand tool can do the job, then that should be the choice. There is no need to make the lives of production and maintenance folks any more difficult. There is a certain sense of beauty in a great tool and I find an aesthetic pleasure in doing a clean design, whatever its level of complexity. Unique solutions to difficult problems are especially satisfying to develop.

I have designed many tools that touch the finished metal of luxury vehicles using simple springs for power. I am also comfortable using air or hydraulic cylinders and servo or stepper motors. My last Vectorworks creation was a seven axis robotic assembly system for electronic components. It used a variety of steppers, servos, vacuum pick up and fluids delivery.

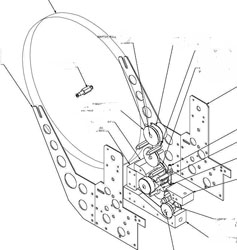

A US Patent (7887283) was recently granted for my wind turbine design. An eight foot diameter testbed model is currently under design and simulation testing. Advanced design is proceeding in Solidworks 2012.

Please contact me to discuss your needs.

Mike Mongan

248 891 6560

email: Mike@m2solids.com